Waste Rubber Pyrolysis Derived Products

Pyrolysis Oil

The pyrolysis derived oil is a dark brown liquid with a specific odor and is 100% suitable for use in any type of liquid fuel industrial burner.

While producing the oil, the waste tire pyrolysis system produces non-condensing gases, part of which are burned in the furnace to provide heat for the continuous pyrolysis process and the remaining gases are burned in a flare or for heating.

Carbon Black

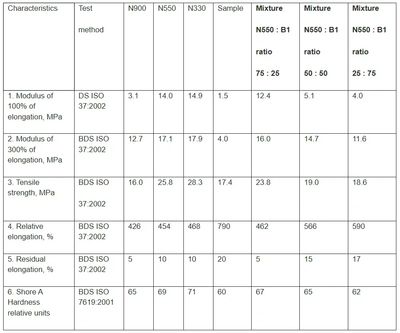

Physico-mechanical characteristics of SBR based vulcanizates, containing different types of carbon black including virgin N330, N550, N900 and our B-1 product sample.

The coarse carbon black can be milled down to micron sizes. See comparison photos of virgin carbon black and our carbon black particles. Laboratory tests including all the relevant specifications of the carbon black is also available. The carbon black can be used either in a mix of virgin carbon black or alone for industrial rubber products.

Also it can be burned as fuel in coal fired furnaces.

B-1 Test sample photos of our Carbon Black and virgin Carbon Black types N550, N330, N900.

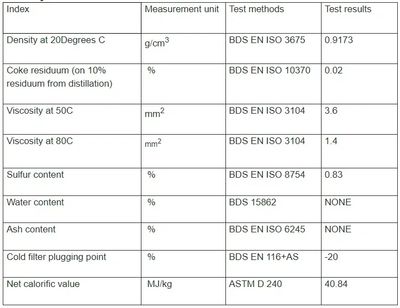

Characteristics of the B-1 carbon black production sample

Further characteristics of the B-1 carbon black production sample

Steel Wires

Feeding Hopper for shredded waste rubber / waste tires

Collected steel wires after the pyrolysis process

The waste tires thick board steel wires can be cut into pellets and used as shots in abrasive applications. All the wires can be melted for metal recovery.

This website uses cookies.

We use cookies to analyze website traffic and optimize your website experience. By accepting our use of cookies, your data will be aggregated with all other user data.